Phone:12345678910

Tel:0550-1234567

Fax:0550-1234567

Address:A certain city in a certain area of a certain street of a certain street

Website:www.mobanzhan.net

CNC machine tool spindle, feed drive organization, rail and other protection and conservation

CNC machine tools, some of the protection and conservation of the first include: machine tool spindle components, feed drive organization, rail and other protection and conservation.

1. Protection and maintenance of spindle parts

Spindle components are some of the primary components of CNC machine tools, mainly by the spindle, bearings, spindle quasi-stop equipment, automatic clamping and chip removal equipment.

CNC machine tool spindle components of the smooth, cooling and sealing machine is the use and protection process worthy of a few questions.

First, the outstanding smooth effect, you can reduce the bearing operating temperature and extended service life; To this end, in the operation to be noted: low speed, the choice of grease, oil circulation smooth; high speed selection of oil mist, oil and gas smooth way. However, when the choice of grease is smooth, the spindle bearing the amount of volume is usually 10% of the bearing space volume, should not be filled, because too much oil, will increase the spindle heat. On the oil circulation is smooth, in the operation and use to be done every day to see the spindle smooth temperature fuel tank, see the oil is not sufficient, if the oil does not work, you should promptly increase the smooth oil; together to pay attention to see the smooth oil temperature scale is not appropriate The

In order to ensure that the spindle has an outstanding smooth, reduce the conflict heat, together with the heat of the spindle components can be taken away, usually use a smooth system, with hydraulic pump strong oil supply smooth, the use of oil temperature controller control tank oil temperature. Advanced CNC machine tool spindle bearings selected high-level grease storage method is smooth, every additional grease can be used 7 to 10 years. The new type of smooth cooling method not only to reduce the bearing temperature rise, but also to reduce the bearing inner and outer ring temperature difference to ensure that the spindle thermal deformation is small.

There are two smooth ways to smooth the spindle, oil and gas smooth approach similar to the oil mist smooth way, but the oil mist is a smooth way to supply oil mist, and oil and gas is smooth and timely quantitative to the mist into the bearing air, so both Finished the oil mist smooth, but also to avoid the oil mist too much pollution of the surrounding air. Spray the smooth way is to use a larger flow of constant temperature oil (each bearing 3 ~ 4l / min) injection to the spindle bearings to achieve smooth, cooling the intention. Where the larger flow of oil injection is necessary to rely on the oil pump forced discharge, rather than natural reflux. Together, but also use a dedicated high-capacity high-precision constant temperature fuel tank, oil temperature control at ± 0.5 ℃.

Second, the cooling of the spindle components is mainly to reduce the bearing heat, effective control of heat mainly.

Third, the spindle components of the seal is not only to avoid dust, dust and cutting fluid into the spindle components, but also to avoid smooth oil leakage. The seal of the spindle part has a touch and non-touch seal. On the use of oil felt and oil-resistant rubber seal of the touch-type seal, pay attention to view its aging and damage; on non-touch seal, in order to avoid leakage, the first is to ensure that the oil can be discharged as soon as possible to ensure that the return hole The

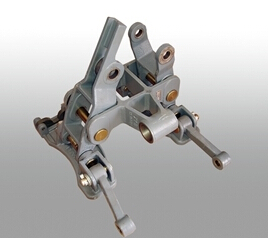

The front axle is supported by a sealed structure

In summary, in the use and protection of CNC machine tools need to pay great attention to the spindle components of the smooth, cooling and sealing questions, and carefully do this work.

2. Feed and drive organization protection and conservation

Feeding transmission organization of the electromechanical components are: servo motor and detection components, deceleration organization, ball screw nut pair, screw bearings, moving parts (workstations, spindle boxes, columns, etc.).

Here the first pair of ball screw nut protection and maintenance of the question to be explained.

(1) ball screw nut auxiliary axial adjustment of the gap

In addition to the need for a single direction of the feed movement accuracy, the ball screw nut pair has a severe demand for axial clearance to ensure reverse transmission accuracy. Therefore, in the operation and application should pay attention to because the screw nuts wear and tear caused by the axial clearance adjustment method used to eliminate.

Double nut gasket

This method is simple and reliable structure, good stiffness, the most widely used in the double nut between the way by the gasket by a professional production plant in accordance with user needs to adjust the pre-tightening force, the use of loading and unloading is very convenient.

Double nut thread type clearance

Use a nut on the external thread, through the nuts to adjust the relative position of the two nuts to complete the preload, adjusted with another round nut after the lock, this configuration adjustment is convenient, and can be used in the process, at any time to adjust , But the preload can not be precise control.

Tooth difference

In the flange of the two nuts are made of cylindrical external gear, and separated from the two ends of the sleeve in the internal gear meshing, the number of teeth separated by z1, z2, and a difference between a tooth. Adjust the time, first remove the ring gear, so that the two nuts on the sleeve in the same direction are rolling a tooth, and then insert the ring gear, the two nuts will attack the relative angular displacement, the axial displacement: Z1, z2 for the gear teeth, ph for the ball screw lead.

(2) Ball screw nuts are sealed with a smooth check

Ball screw nuts and the smooth seal of the usual view is that we use the operation to pay attention to the question. On the screw nut seal, that is, pay attention to check the seals and protective cover to avoid dust and impurities into the ball screw nut vice.

On the screw nut is smooth, if the choice of grease, then regular smooth; if the use of smooth oil will have to pay attention to often through the oil filling hole.

3. Machine guide rail protection and conservation

The protection and maintenance of the machine tool guide is mainly the smooth rail and rail protection.

(1), smooth rails

The smooth purpose of the guide rail is to reduce the resistance of the conflict and the wear and tear to avoid low speed crawling and lowering the temperature rise at high temperatures. So the smooth rail is very important. On the sliding guide, the choice of smooth oil smooth; and rolling guide, then the smooth oil may be smooth. CNC machine tools commonly used smooth oil are: l-an10,15,32,42,68. Rail smoothing is usually used automatically smooth, we should pay attention to the use of operation in the automatic smooth system to see the flow distribution valve, if it is faulty will form a guide rail can not automatically smooth. In addition, it is necessary to do it every day

See the smooth oil tank guide oil, if the oil does not work, you should promptly increase the smooth oil; together to pay attention to see the smooth oil pump is not punctual start and stop, but also pay attention to check the punctual start is not able to supply smooth oil.

(2), guide rail protection

In operation, please pay attention to avoid the chip, abrasive or cutting fluid may be scattered on the guide surface, otherwise it will cause the rail wear and tear, abrasion and corrosion. To this end, pay attention to the rail protection equipment, usually check to ensure the protection of the rail.

4, reverse the protection and maintenance of the operating platform

CNC machine tool circular feed movement is usually done by the reverse operation of the table, on the processing base, reverse the work desk has become a short few parts. Therefore, in the operation and application to pay attention to the operation of the reverse in accordance with the instructions and operational procedures for the correct operation of the operating procedures. Pay special attention to reversing the smoothness of the operating platform and guide rails.