Phone:12345678910

Tel:0550-1234567

Fax:0550-1234567

Address:A certain city in a certain area of a certain street of a certain street

Website:www.mobanzhan.net

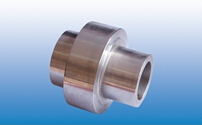

Distortion Control of Carburizing and Quenching of 17CrNiMo6 Steel Heavy - duty Inner Ring Ring

Due to the development of modern industry, the requirement of mechanical parts for gear transmission is more and more high, which requires comprehensive mechanical properties such as wear resistance, surface contact fatigue and bending fatigue resistance. Heat treatment is a key process in the production of gears, mainly for gear carburizing quenching treatment, its main problem is the distortion of the gear. There are many factors that affect the gear distortion, and many factors interact with each other, it is difficult to control, the production often produce distortion due to distortion of waste, carburizing quenching distortion has become one of the technical difficulties in the domestic and foreign gear manufacturing.

Large-scale heavy-duty internal gear ring in large-scale construction machinery gear box has a wide range of applications, because of its large size, and are thin-walled structure, such parts distortion is not easy to control. In the carburizing and quenching process, if the heating or cooling will cause unreasonable uneven expansion of the workpiece, resulting in ring gear distortion. The distortion of inner ring gear mainly includes two aspects of ellipticity and taper. In this paper, two basic points of carburizing quenching process and tooling are improved in combination with actual production. The distortion degree of internal ring gear is controlled to a low range .

From the aspects of process and tooling, the control of internal ring gear distortion is studied. The conclusion is:

1) The inner ring ring carburizing process to increase a stress-relief annealing, the annealing temperature is much lower than the carburizing, quenching temperature, and the heating rate is slow, is conducive to the release of processing stress.

2) The pre-carburizing temperature rise step and strictly control the heating rate of 60 ℃ / h, can reduce the various parts of the ring gear due to uneven heating caused by the temperature difference to ensure a stable austenite transformation rate, and the relative Lower carburizing temperature and quenching medium temperature, can reduce the thermal stress and tissue stress, to a certain extent, reduce the degree of distortion of the ring gear.

3) The positioning sleeve of the inner tooling can form a good fit with the inner ring gear during quenching to limit the ellipticity and taper distortion of the inner ring gear, and the multi-point support can improve the heat transfer efficiency so that the inner ring gear parts Heat evenly, reducing the heat treatment process due to the quality of the workpiece itself is too large and the uneven force caused by the distortion.

4) The process of small-scale production and tooling, can control the oval in the 0.40 ~ 0.70 mm, taper control in the 0.28 ~ 0.52 mm, the average relative to the internal diameter of the inner diameter of the distortion rate was 0.036% and 0.027 %, With a large-scale mass production and application conditions.