Phone:12345678910

Tel:0550-1234567

Fax:0550-1234567

Address:A certain city in a certain area of a certain street of a certain street

Website:www.mobanzhan.net

Positive extrusion, reverse extrusion and composite extrusion are the three most widely used methods in cold extrusion

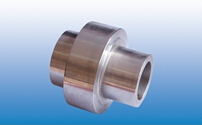

Precision cold extrusion is the metal blank on the cold extrusion die cavity, at room temperature, through the press on the fixed punch to the blank pressure, so that the metal blanks produced plastic deformation and parts of the processing method.

1. Positive Extrusion: Positive extrusion, the metal flow direction and the direction of movement of the punch. Positive extrusion can produce solid and hollow pieces of various shapes.

2. Anti-extrusion: reverse extrusion, the metal flow direction and the direction of movement of the punch opposite. Counter-extrusion can be obtained in various shapes of cup-shaped pieces.

3. Composite extrusion: extrusion, the rough part of the metal flow direction and punch the same direction, while the other part of the metal flow direction and the punch movement in the opposite direction. Composite extrusion can be obtained all kinds of cups, rods, cylinder parts.

4. Radial extrusion; extrusion, the metal flow direction and the direction perpendicular to the punch movement. Radial extrusion can be divided into centripetal extrusion and centrifugal extrusion, radial extrusion used to make helical gears, spline and other parts.

5. Forging: Forging pressure, the metal blank radial outward flow. Upset for the manufacture of the flange with the shaft parts or flange cup-shaped parts.

Positive extrusion, reverse extrusion and composite extrusion are the three most widely used methods in cold extrusion. The direction of their metal flow parallel to the axis of the punch. Therefore, there are a lot of information, also known as the three methods for axial compression. As previously described, axial compression can be made of a variety of solid and hollow parts, such as ball pin, bobbin shell, shell and so on. Radial extrusion is the last ten years to develop, mainly for communications equipment, dial, bike, such as the keyboard.

These are some of the basic cold extrusion deformation, with the development of cold extrusion technology, and sometimes cold volume forging, etc. will be attributed to the cold extrusion.

Precision cold extrusion in the automotive, high-speed rail, aircraft, tractors, bearings, telecommunications equipment, instruments and other mechanical and electrical manufacturing, or in bicycles, sewing machines and other light industry, and defense industry systems are widely used, it is because it Has obvious advantages.